Tom Erik Vange

Member of Powertrain department

Managing: FUEL AND COOLING

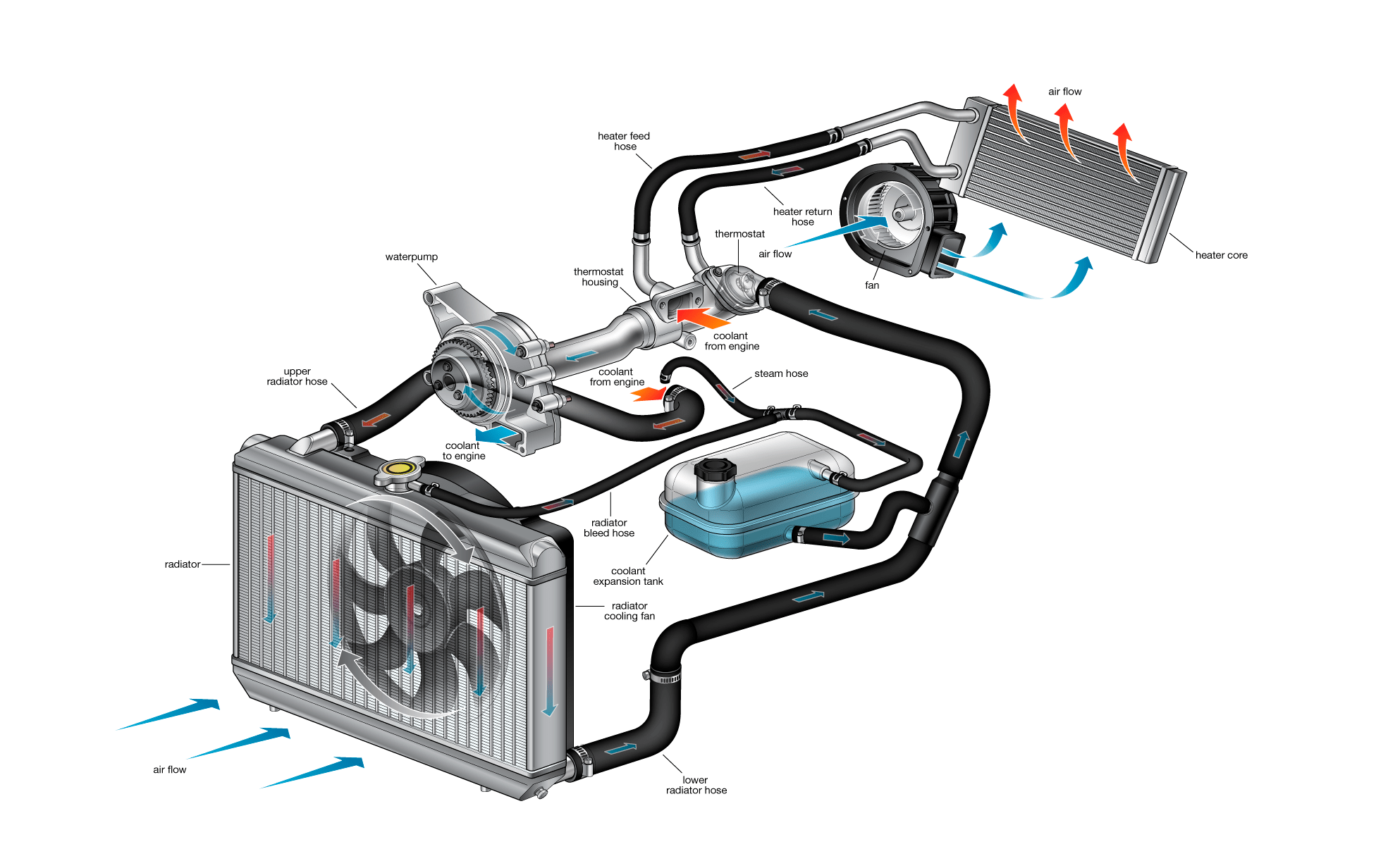

A vehicle’s engine-cooling system serves not just to keep the engine cool, but to also keep its temperature warm enough to ensure efficient, clean operation.

In other words, The cooling system keeps everything cool.

Cooling system AR20

This year’s cooling system was drastically downscaled in comparison to last year’s setup. We decided that we wanted to try with only one radiator, and an even smaller one at that. This was mainly because our engine had a hard time to heat up, and when the pump started, the temperature would drastically drop. For this year, we wanted to try pulse-width modeling with a smaller cooling system. The total amount of water in the system is calculated to be 1,5 L.

Components

The radiator used on our car was donated by one of our sponsors, Grimstad Chiptuning.

The fan connected to our radiator was the same as the one used on AR19.

The pump used was of the type “EBP40“.

Since we had no sidepod on this years car, we made a ducting on the front of the radiator, and a fancowl from the radiator backside and to the fan.

Main rules and regulations

According to the rules of FSAE:

- We are only allowed to use plain water in our cooling system.

- The expantion tank/refilling has to be at least 10% the volume of the system.

- Any material used in the cooling system is required to withstand temperatures specified by the rules.

- The driver must be shielded from any possible source of spilling (and high temperatures around the cooling system).

Testing and verification

To test the effect of the cooling system, we rigged up a test-system with the radiator, cooling pipes and a bowl of boiling water on a stove. This test was used to find the Δt (difference in temperature) from when the water entered the system, and when it got out of the system.

There are also data from Solan (AR19) at endurance in the archive, where you can see that the cooling system was too effective. It should also be data from AR20 out in archive with the different senarios of no duct-no fan, no duct with fan, and with duct and fan.

Testing setup

For the test setup, a boiler on a oven was used. It is importen when testing the cooling system that the pump gets no air pocket in the system, so that it can manage to push the water around the system. This should also be in mind when designing the finished system on the car. Also take note that you don’t get airpockets in any pipes or hoeses.

Choice of components

The choise of components for AR20 was mainly for downsizing, less efficient and aiming for a lighter system.

Take a look at what the original motor came with of parts and specs. Aim for simmular setup, but also take into an account that the engine might get less air-cooling while riding, the use of a tubo and simular factors.

Also when choosing electrical components, be in contact wiht electro. It is important not to exceed the power-budget, so that the car can manage to drive entire endurance without the risk of draining the battery completely.

Radiator

The first radiator for AR20 was ment to be modified and converted into a dual-pass radiator (water crosses the core 2 times). Found a cheep radiator, and started designing the side tanks, but before the label started it got confronted that the radiator could not be welded, therefor it ended on the shelf. The reason for it could not be welded was it had bushings in it, which would melt during welding, and we would get several leaks.

Therefore:

If you aim for modifiing the radiator, get a core which can be welded, and design the side tanks from there.

There are not many radiator in the size like AR20 or AR19, (manly car radiators are too big, and mc radiators are a bit expencive) but there might me some aircondition radiator in this size (Fun fact: AR19 are aircondition-radiator from some construction machine, and AR20 are an aircondition-radiator from a mark 5 supra).

Take into an account the ports of the radiator and placement, considering potential leaks and air pockets.

Fan

The fan for AR20 and AR19 is the same model, which hase a great power, is fairly small and fit into the power-budget.

Pump

Since we tok aim at downsizing the cooling system compared to AR19, a smaller pump whas choosen. Davies craig has a great selection of pumps. The AR20 pump can pump 34 L/min. With the use of an electric pump, you can run the cooling system, even if the motor is off. The pump can me PWM (Pulse width modulation) so you can get f.instance 3 setting where the pump can go slow, medium and at full speed, depending of the engine temp. Talk with electro for such a setup.

Tubing

For AR20 the choice of using pipes instead of hoeses where made for saving weight. Tip: Use AN-fittings. It will make it easeier for setting up and changing parts in the system and assembly.

Depending of the pipes size and thicknes you might need to cut and weld, or maybe bend it. The technique used on AR20 whas bending with the help of filling the pipe with sand, cap’ing both ends, warm the pipe up with a heat gun and use a “pipe-bender” at UIA’s lab. (simular to this, except we clamped the ends with a vise, and filled with sand from the beach).

Aim for around the same pipe size as the engine outlet. Then use silicon hose at all transition needed. Make sure that the claps holding the hoeses on have something to prevent them from sliding off.

Controll-check with the user manual of the motorbike/engine while designing (f.instance, flow of water, total capacity and similar).

For the 4LC TKM 690 ccm motor, the frow of the water is:

– Out of the top port of the engine.

-> AN-fitting with return from turbo connected.

– Radiator inlet, through the radiator.

– Radiator outlet to inlet on cooling pump (center front).

– Out from pump.

-> AN-fitting delivery to turbo.

– In the lowest port of the engine.

Importent to have the expantion-tank/cooling resevoir at the highest point of the system, preventing air pockets geting trapped in the system, and connecting it to “the main loop” at the highest point (around the engine outlet).